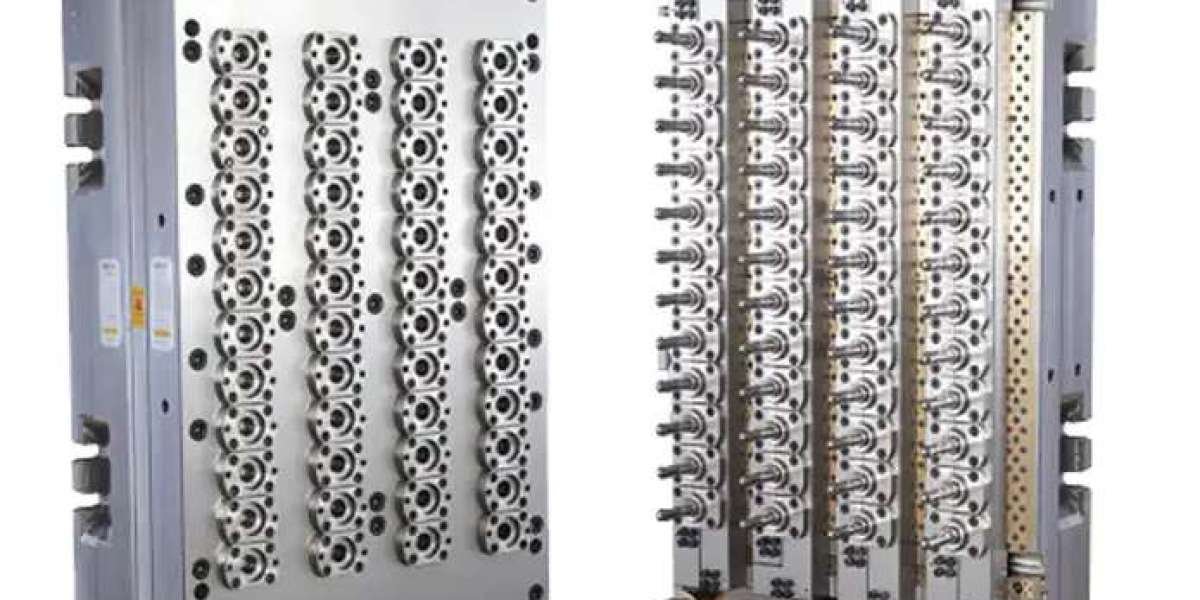

Pet Preform Mold plays a central role in manufacturing plastic bottles and containers, providing the foundation for consistent, reliable products. Each cavity must maintain precise dimensions and uniform wall thickness to ensure bottles meet functional and aesthetic standards.

Cavity design directly affects material flow and preform uniformity. Pet Preform Mold engineering ensures that molten PET distributes evenly, preventing weak points and supporting consistent blow molding. Minor deviations in mold design can cause defects, including uneven walls, bubbles, or deformation.

Temperature control is critical for repeatable performance. Pet Preform Mold uses heating and cooling channels to regulate plastic viscosity and prevent stress concentrations. Effective thermal management allows molds to maintain cycle speed without sacrificing structural integrity.

Material choice influences durability and accuracy. Hardened steel and specialized alloys provide long-term resistance to wear and corrosion. Pet Preform Mold benefits from high-quality materials, ensuring dimensional stability during thousands of production cycles.

Flow systems, including gates and runners, must balance pressure and speed. Uniform distribution of molten material reduces waste and ensures preform clarity and strength. Pet Preform Mold design minimizes turbulence and ensures each cavity produces a preform suitable for filling and labeling.

Maintenance supports continuous production. Regular inspections, cleaning, and lubrication prevent residue buildup and maintain cavity precision. Pet Preform Mold care reduces downtime and extends operational lifespan, supporting high-volume output.

Customization allows production flexibility. Adjustable cavities accommodate different bottle sizes, shapes, and neck finishes. Pet Preform Mold versatility allows manufacturers to respond to changing product lines without major tooling changes.

Automation improves efficiency. Pet Preform Mold integrates with injection machines, conveyors, and robotic handling systems, enabling precise cycle control and minimizing manual intervention. Automated setups maintain consistent quality and reduce human error.

Testing ensures molds produce compliant preforms. Measurements of weight, dimensions, and clarity confirm accuracy and repeatability. Pet Preform Mold performance directly impacts downstream operations, including blow molding and packaging.

Pet Preform Mold combines engineering, durability, and precision. Careful cavity design, thermal regulation, and material selection provide reliable preforms, supporting smooth beverage bottle production. Proper maintenance and automation integration further enhance efficiency and product quality.